July 27, 2015

Wafer-thin super material heralds the future of wearable technology

A ‘flat-pack’ construction of a powerful new supercapacitor paves the way for wearable and miniature electronics.

UOW’s (ISEM) has successfully pioneered a way to construct a flexible, foldable and lightweight energy storage device that provides the building blocks for next-generation batteries needed to power wearable electronics and implantable medical devices.

The conundrum researchers have faced in developing miniature energy storage devices, such as batteries and supercapacitors, has been figuring out how to increase the surface area of the device, to store more charge, without making it larger.

“Among all modern electronic devices, portable electronics are some of the most exciting,” ISEM PhD student Monirul Islam said. “But the biggest challenge is to charge storage in a small volume as well as being able to deliver that charge quickly on demand.”

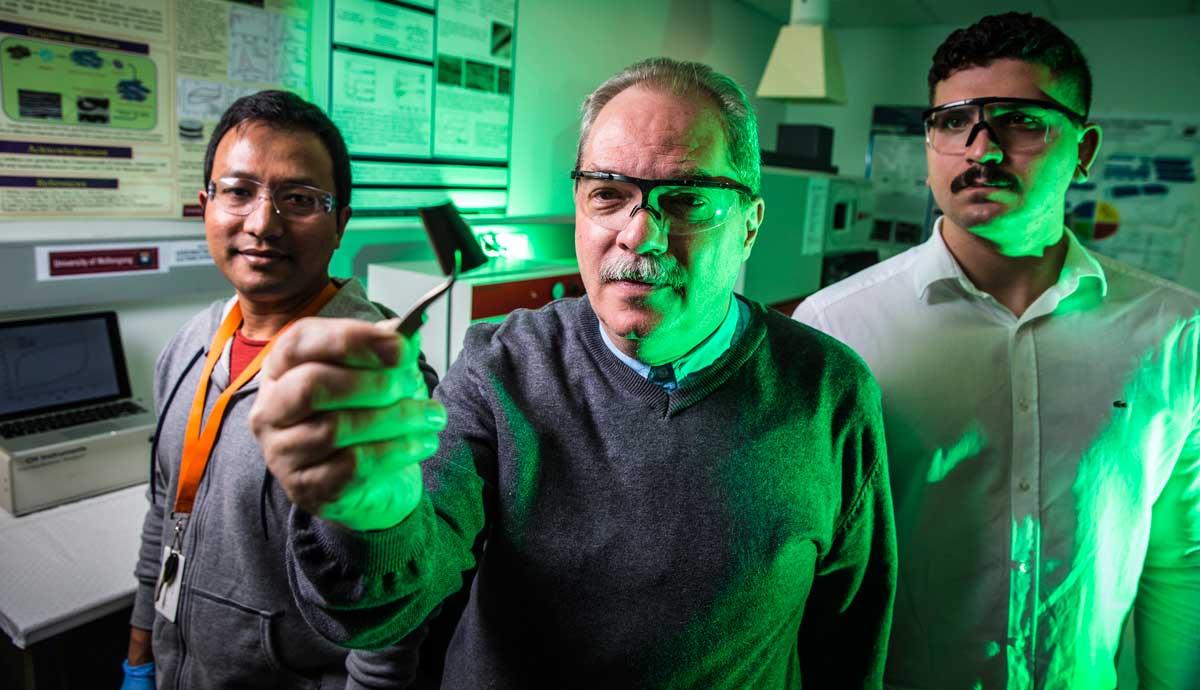

To solve this problem, a team of PhD students, led by Dr Konstantin Konstantinov under the patronage of ISEM Director Professor Shi Xue Dou and with the support of Professor Hua Kun Liu, the head of ISEM Energy Storage Division, have developed a three-dimensional structure using a flat-pack self-assembly of three components: graphene, a conductive polymer and carbon nanotubes, which are atom-thick lattice-like networks of carbon formed into cylinders.

The so-called wonder material graphene, made from single atom-thick layers of graphite, was a suitable candidate due its electronic performance and mechanical strength.

“We knew in theory that if you can make a sort of carbon skeleton you have a greater surface area and greater surface area means more charge,” Dr Konstantinov said. “If we could efficiently separate the layers of carbon we could then use both surfaces of each layer for charge accumulation. The problem we faced was that fabricating these 3D shapes in practice, not just theory, is a challenging, if not impossible task.”

The solution was to flat-pack the components by building the 3D shape layer-by-layer, much like a miniature exercise in cake decoration. The graphene in liquid form was mixed with the conductive polymer and reduced to solid and the carbon nanotubes carefully inserted between the graphene layers to form a self-assembled flat-packed, wafer-thin supercapacitor material.

“The real challenge was how to assemble these three components into a single structure with the best use of the space available,” PhD student Monirul Islam said. “Getting the proportions or ratios of the components appropriately in order to obtain a composite material with maximum energy storage performance was another challenge.”

Wrong proportions of either ingredient result in a lumpy mess, or a 3D shape that isn’t strong enough to retain the needed flexibility as well as the charge storage ability. There’s also elegance in the simplicity of the team’s design: the researchers dispersed the components in liquid crystalline, which enabled natural chemical interactions to prevent the graphene layers clumping together.

The result was a 3D shape with, thanks to the carbon nanotubes, a massive surface area, excellent charge capacity that is also foldable. It can also be cheaply and easily fabricated without the need for expensive vacuum chambers or sophisticated equipment.

“Our graphene-based flexible composite is highly conductive, lightweight, is able to fold like a roll or stack like a paper in electronic devices to store a huge amount of charge,” Monirul said. “This material can store charge in a second and deliver the charge in superfast speed and will be more lightweight than traditional batteries used in present day’s electronics.”

The ISEM study has been financially supported by the Automotive Australia 2020 CRC as part of its research into electric vehicles. ISEM is the program leader for electrification and plays crucial role for design of next generation electric vehicles A key to unlocking the electric vehicle’s capability is a lightweight and powerful battery pack.

“Our simple fabrication method of eco-friendly materials with increased performance has great potential to be scaled up for use supercapacitor and battery technology. Our next step is to use this material to fabricate flexible wearable supercapacitors with high power density and energy density as well as large scale supercapacitors for electric vehicles.”

The research was recently published in the journal .